Q-Program

EF-TEK gives customers Unparalleled value and confidence with Q-PROGRAM.

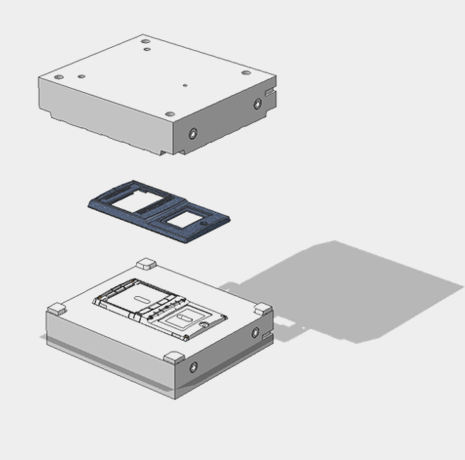

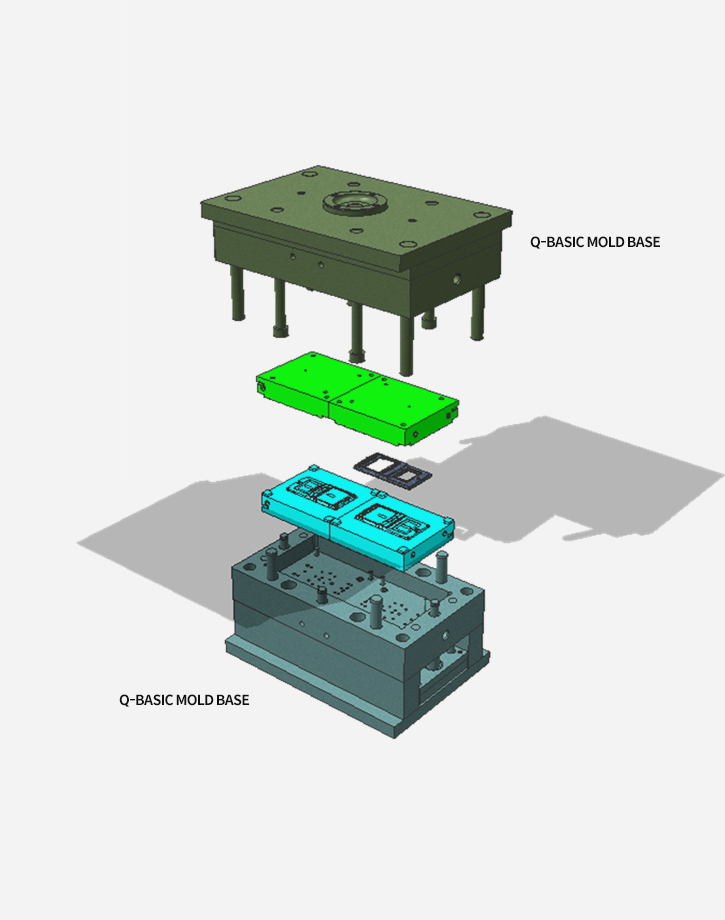

Q-Basic

- Key characteristics

-

Method where only the core is produced by using

EF-TEK's standard Q-Program mold base.

Mold production is possible at mock-up manufacturing cost.

It allows you to identify injection molding issues such as moldability and assemblability that cannot be detected in mock-up products, and to improve mass-production molds by correcting the mold design.

Material DR7079 (Duralumin) is used, and up to 1,000 shots are guaranteed.

You can select the injection material you desire. It is convenient for clients

to produce samples as it takes only a short period of time for delivery.

Production takes approx. 7 to 15 days with only 30~40% of the general costs

required for mass production dies and molds.

The UNDER CUT removal method uses manual extraction, and depending on the length and shape, the production method may need to be changed to Q-ADVANCE, Q-PRO, or Q-MASS

It may require further post processing as core cooling, hot water, and

hot oil are not installed.

"Q-Basic" information

- Core material: Aluminum (DR 7079)

- Mold base: EF-TEK’s Q-PROGRAM MOLDBASE is used.

- Guaranteed quantity of dies and molds: 1,000 shots

- Production Cost: 30–50% of a mass production mold

- Projection period: 7 days to 15 days

※ The production period is subject to change depending on the model and item.

Gallery

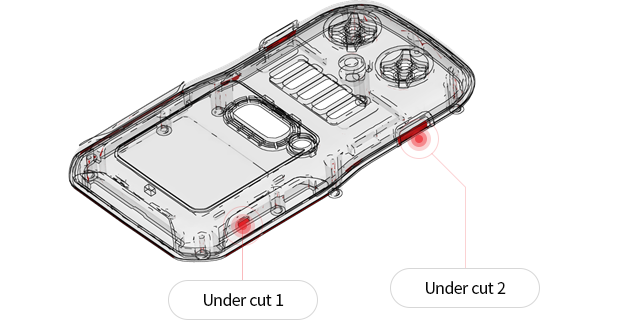

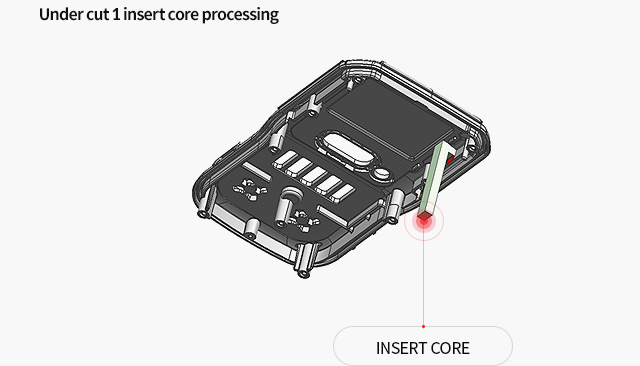

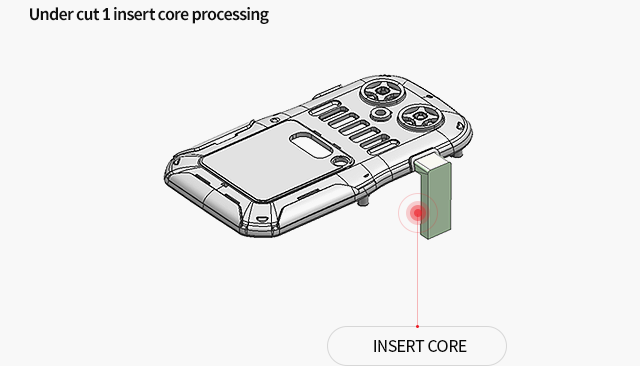

Undercut processing method

- Q-Basic Undercut is a manual processing method.

- Depending on the length and shape of Undercut, it may require “Advanced”, “Pro”, “Mass” production.

- Please request a quote online and make a further inquiry.

“Basic” dies and molds basic information

- Core material : Aluminum (DR 7079)

- Mold base : EF-TEK’s Q-PROGRAM MOLDBASE is used.

- Guaranteed quantity of dies and molds : 1,000 shots

- Production Cost : 30–50% of a mass production mold

- Projection period : 7 days to 15 days