Q-Program

EF-TEK gives customers Unparalleled value and confidence with Q-PROGRAM.

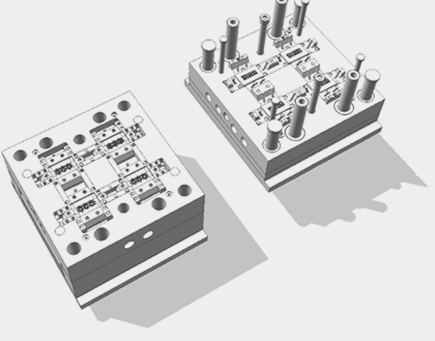

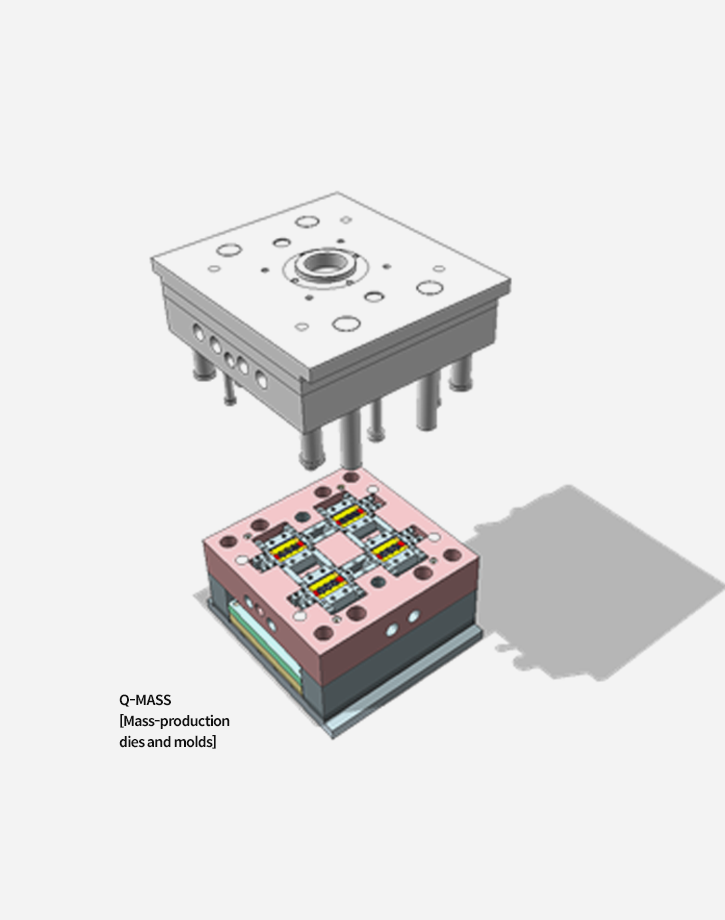

Q-Mass

- Key characteristics

-

These are “Mass” production dies and molds.

It can be used to make various shapes of products and

is ideal for products for mass production.

Various mold base methods can be applied.

Supports various types of gates for both COLD RUNNER and HOT RUNNER systems.

Supports various UNDERCUT methods, including hydraulic cylinders and rotary cores.

“Q-Mass” information

- Core material : KP4M(P20), STD61(H13), NAK80(P21),

STAVAX(420), etc. - Guaranteed quantity of dies and molds : Up to 400,000 shots

- Manufacturing time : 30 days or more

(varies according to the shape) - The manufacturing material for the Q-Mass dies and molds changes according to the shape and injection material.

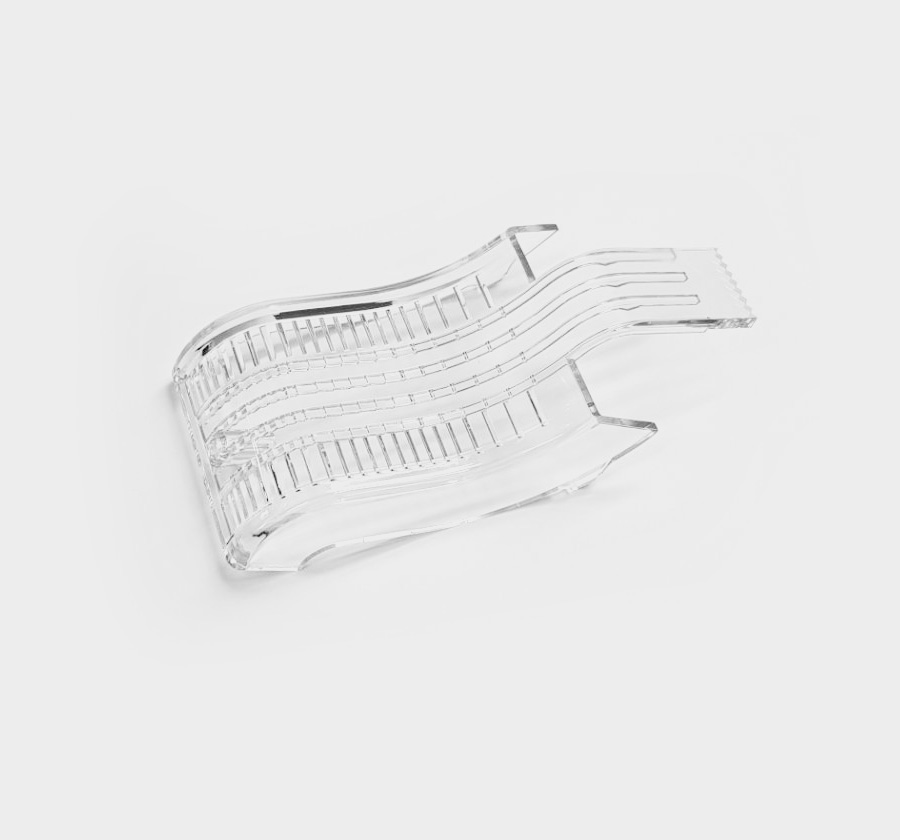

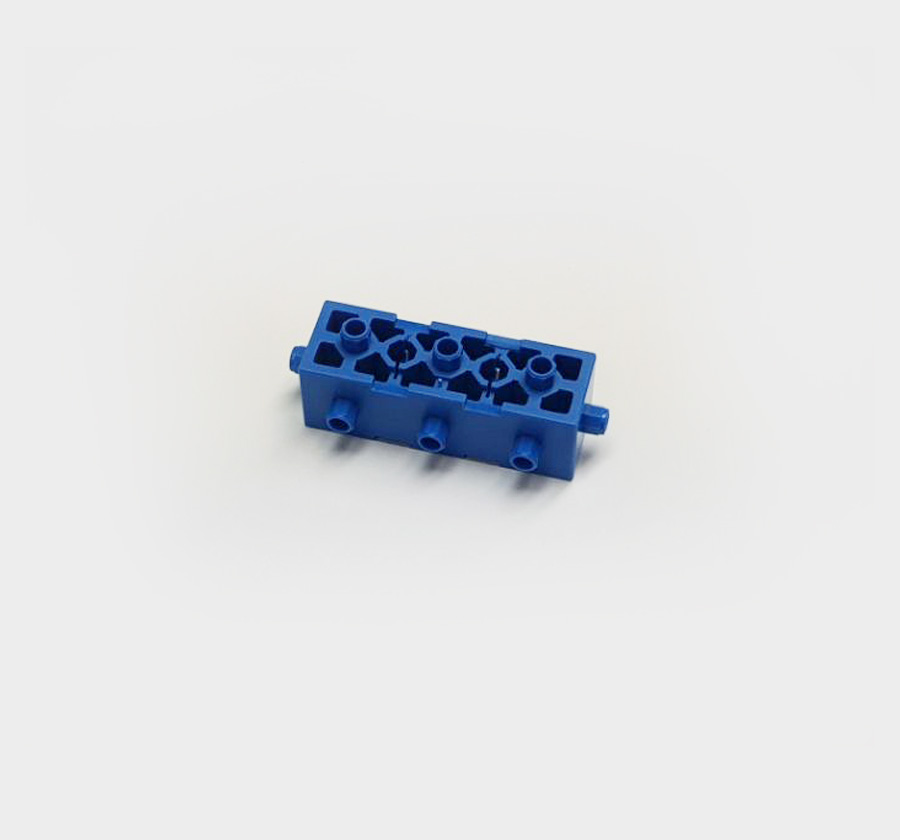

Gallery

“Mass” dies and molds basic information

- Core material : KP4M(P20), STD61(H13), NAK80(P21),

STAVAX(420), etc. - Guaranteed quantity of dies and molds : Up to 400,000 shots

- Manufacturing time : 30 days or more

(varies according to the shape)

The manufacturing material for the Q-Mass dies and molds

changes according to the shape and injection material.