Q-Program

EF-TEK gives customers Unparalleled value and confidence with Q-PROGRAM.

Q-Advance

- Key characteristics

-

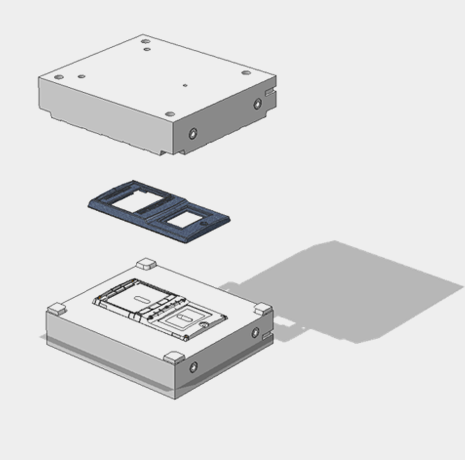

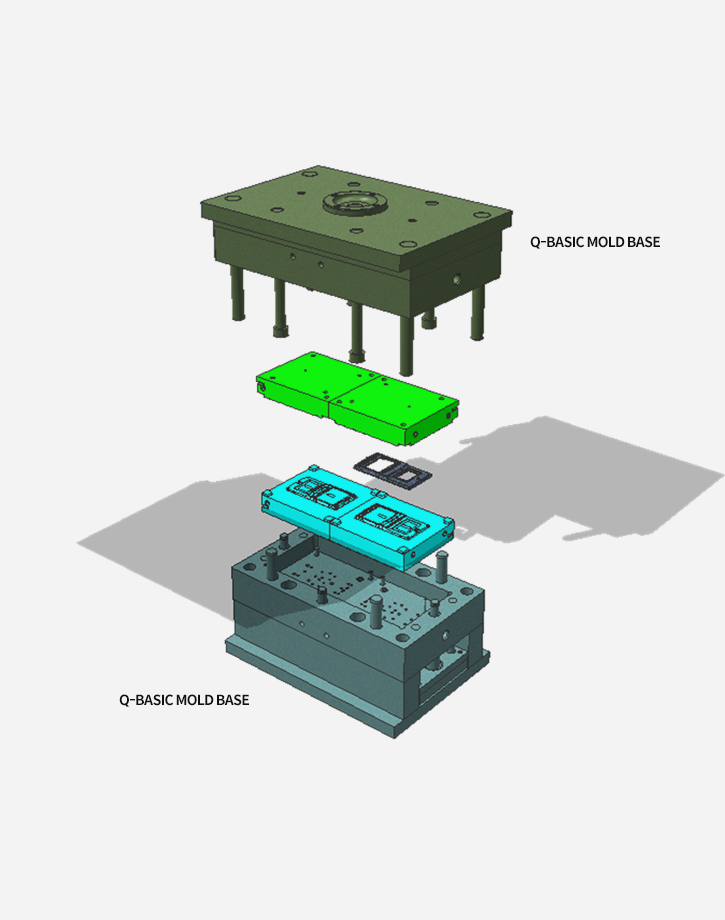

Method where only the core is produced by using

EF-TEK's standard Q-Program mold base.

It is suitable for application to clients’ newly developed products, and its easy mold modification and repair help reduce initial development costs.

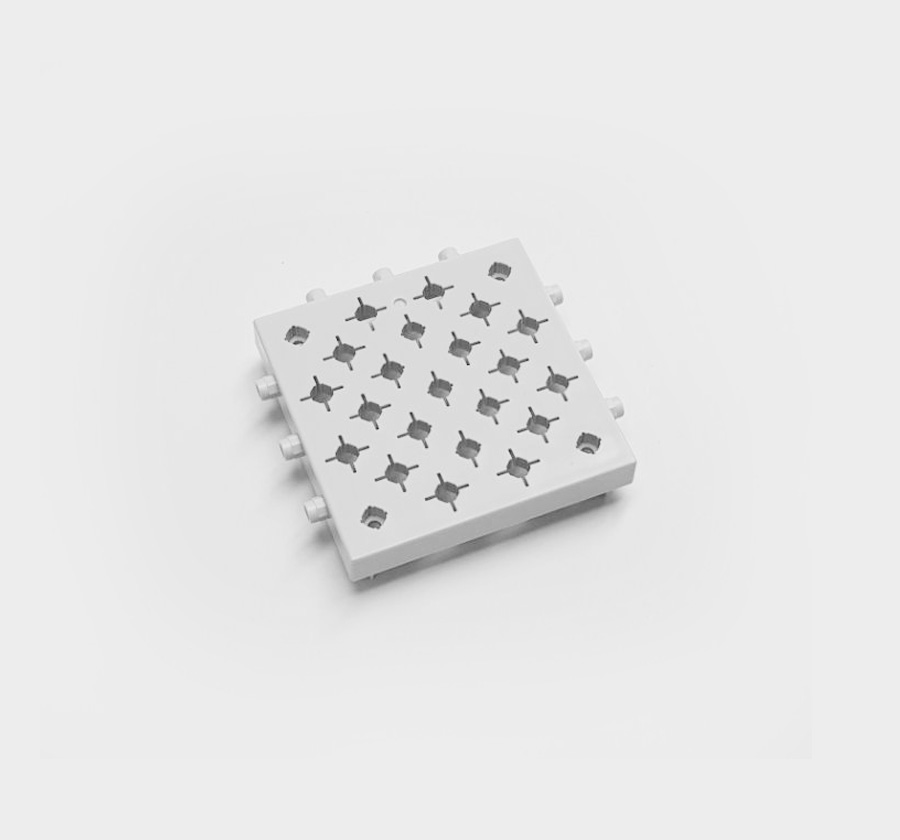

A mold manufacturing method specialized for small-lot, multi product production.

It is possible to produce products, and supply customers

before manufacturing the dies and molds for mass production.

When transitioning to mass-production molds, molds can be manufactured based on the improvements, modifications, and repairs made in Q-ADVANCE, allowing a fast transition to mass-production molds without additional issues.

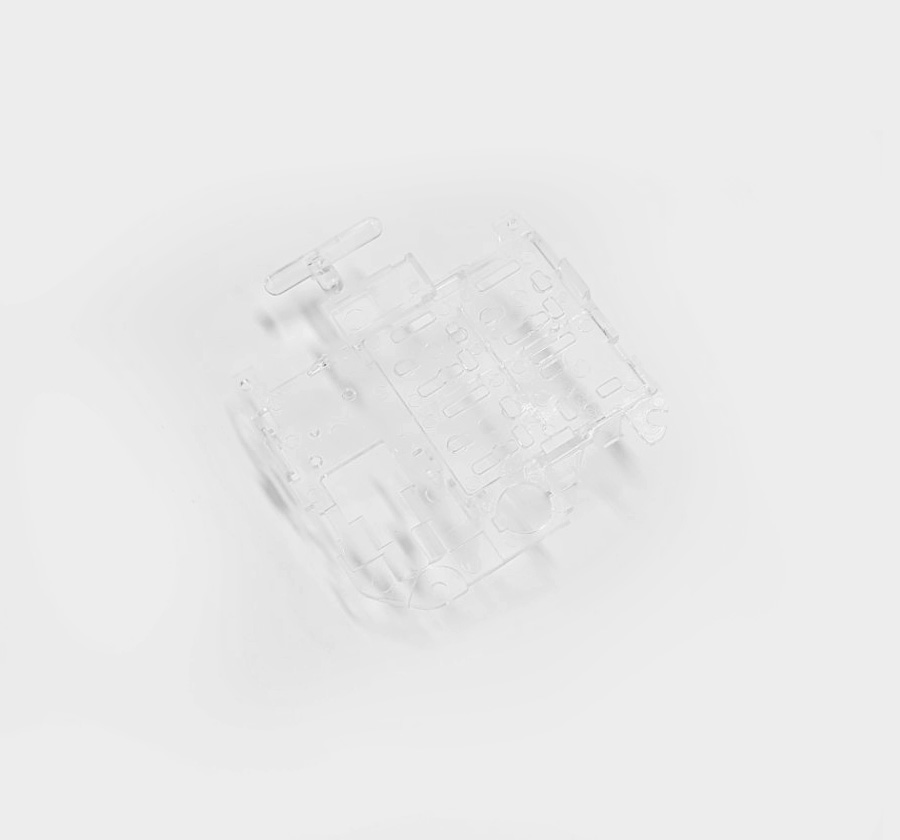

KP4M material is used to produce the core, and up to 50,000 shots are guaranteed.

You can select the core material and injection material you desire.

Production takes approx. 10 to 20 days with only 50~60% of the general costs required

for mass production dies and molds.

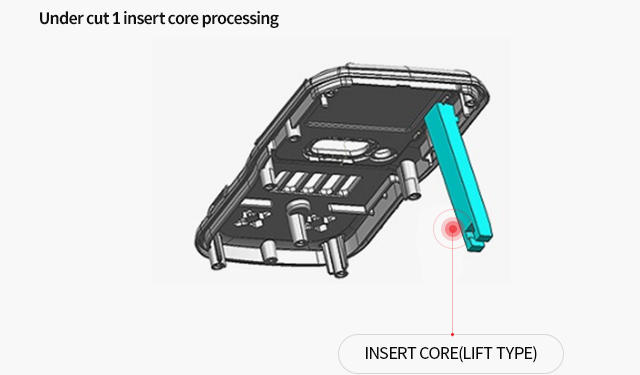

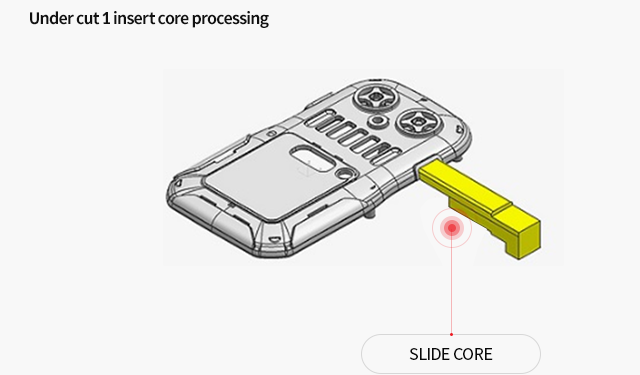

The UNDER CUT removal method uses manual extraction, and depending on the length and shape, the production method may need to be changed to Q-PRO, or Q-MASS.

It may require further post processing as core cooling, hot water, and

hot oil are not installed.

“Q-Advanced” information

- Core material : HP4M, SKD61, NAK80, STAVAX

- Mold base : EF-TEK’s Q-PROGRAM MOLDBASE is used.

- Guaranteed quantity of dies and molds : 50,000 shots

- Manufacturing cost: approximately 50–60% of the mass-production mold cost

- Projection period : 10 days to 20 days

※ The production period is subject to change depending on the model and item.

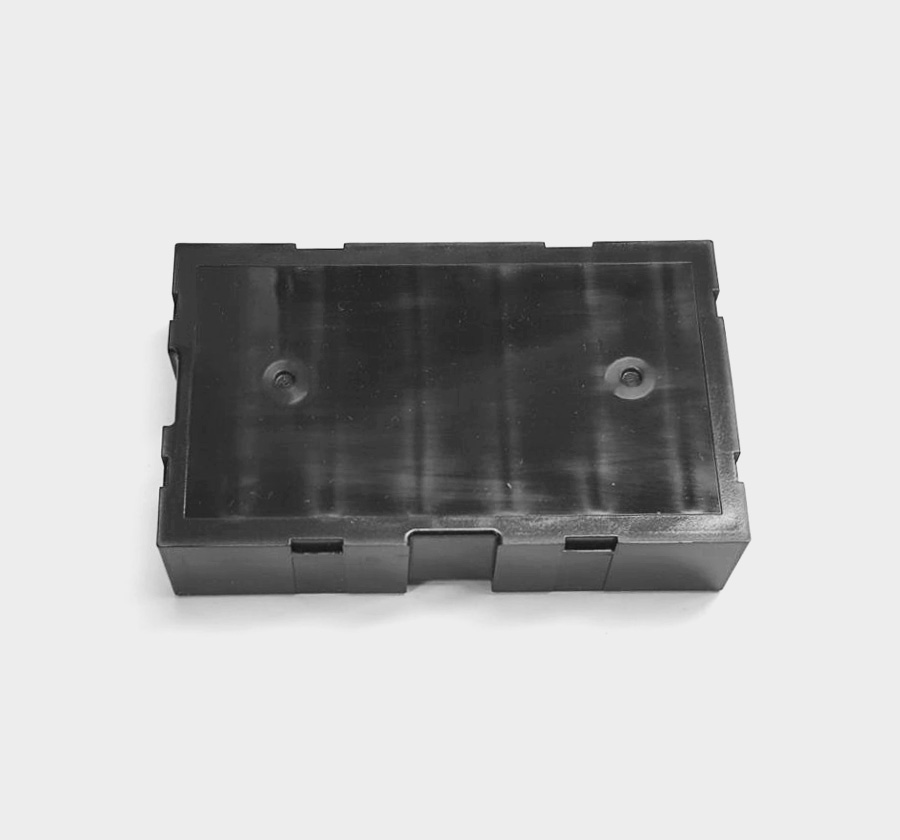

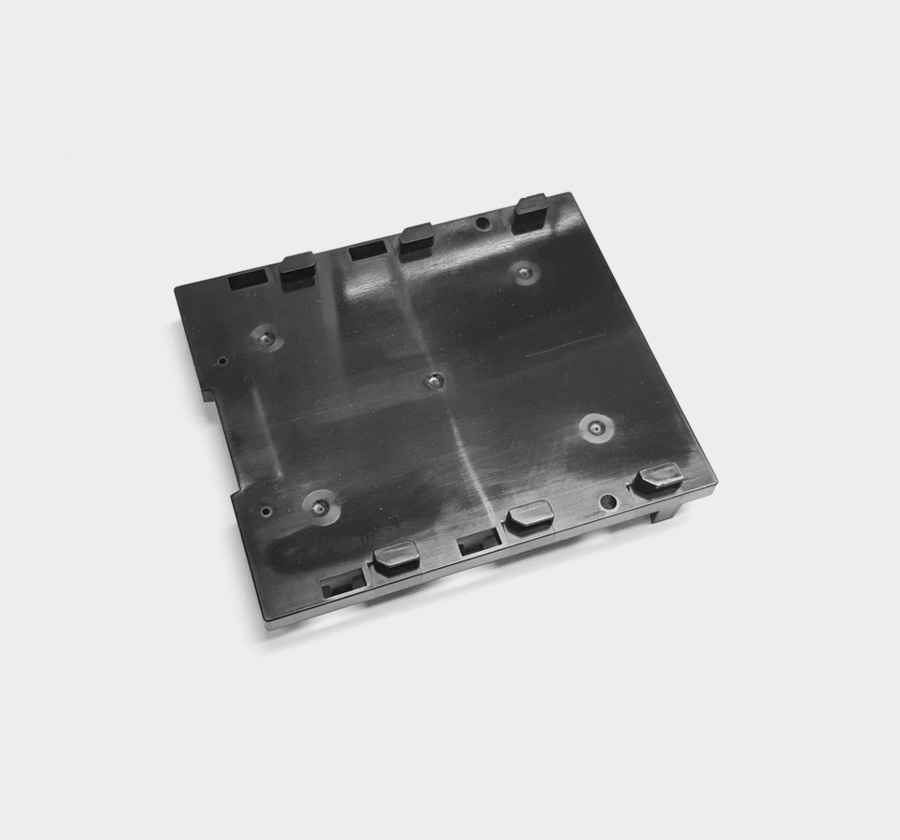

Gallery

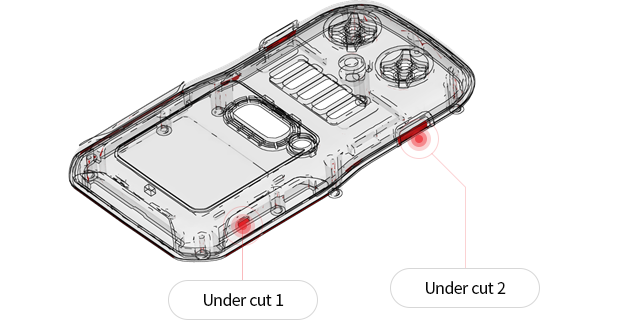

Undercut processing method

- Q-Advance Undercut processing is the same as

mass-production dies and molds. - Depending on the length and shape of Undercut, it may require “Pro” or “Mass” production.

- Please request a quote online and make a further inquiry.

“Advanced” dies and

molds basic information

- Core material : KP4M(P20), STD61(H13), NAK80(P21), STAVAX(420),etc

- Mold base : EF-TEK’s Q-PROGRAM MOLDBASE is used.

- Guaranteed quantity of dies and molds : Up to 50,000 shots

- Manufacturing cost: approximately 50–60% of the mass-production mold cost

- Projection period : 10 days to 20 days